The cost for gear grinding machine is really high, it is so important to take it care well enough for getting longer working with more profit, but how? Taking care of a gear grinding machine involves a combination of regular maintenance, proper usage, and adherence to safety protocols. Here’s a comprehensive guide on how to maintain and care for a gear grinding machine:

1. Regular Maintenance

Daily Checks

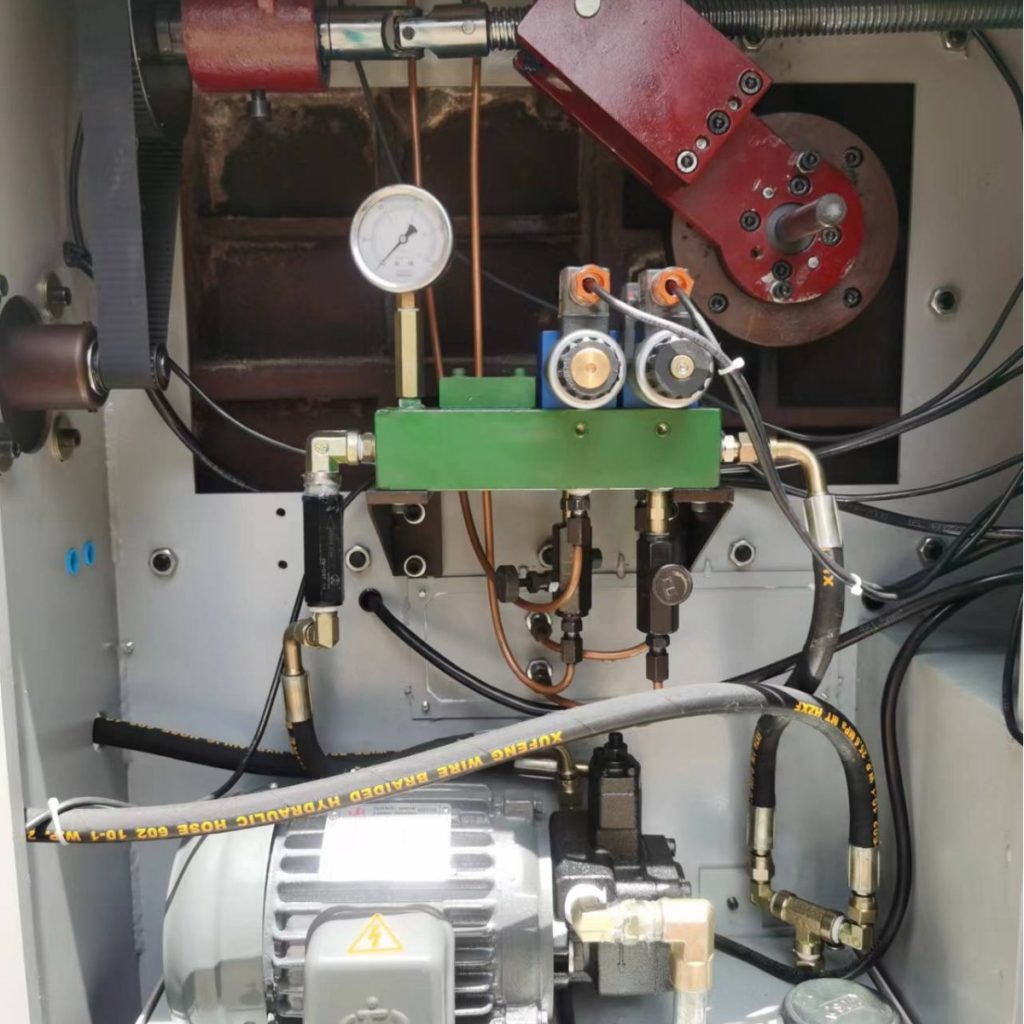

- Visual Inspection: Check for any visible signs of wear or damage, such as cracks, leaks, or loose parts.

- Lubrication: Ensure that all moving parts are adequately lubricated. Follow the manufacturer’s guidelines for the type and amount of lubricant to use.

- Coolant System: Check the coolant level and condition. Clean or change the coolant as necessary.

- Filters: Inspect and clean or replace air and coolant filters to maintain proper airflow and filtration.

- Belt Tension: Check belt tension and adjust or replace belts if they are loose or worn.

Weekly/Monthly Checks

- Bearings: Listen for any unusual noises that could indicate bearing wear or failure.

- Hydraulic System: Check hydraulic fluid levels and condition. Replace fluid if it appears dirty or contaminated.

- Electrical Components: Inspect electrical connections and components for any signs of damage or wear. Ensure all connections are tight and secure.

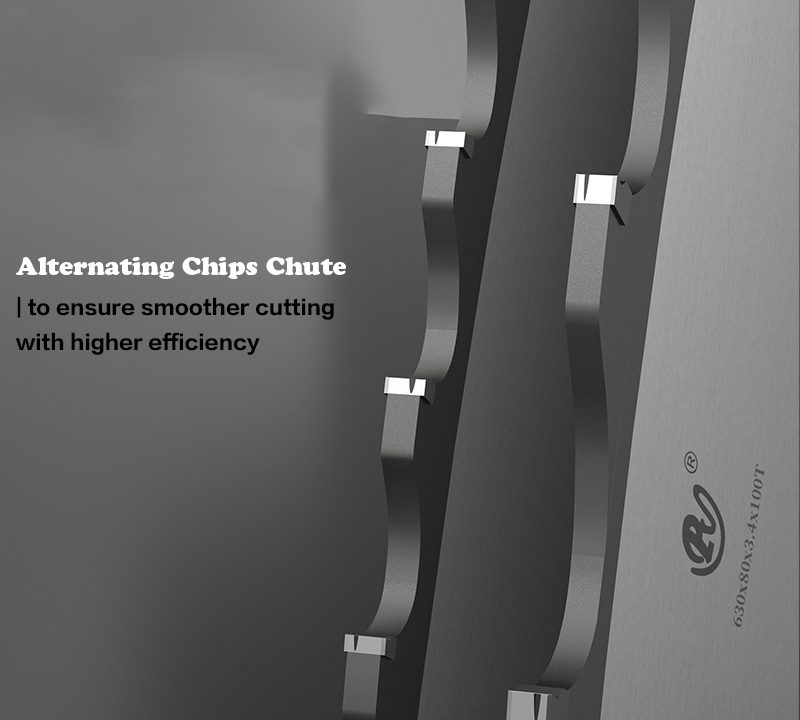

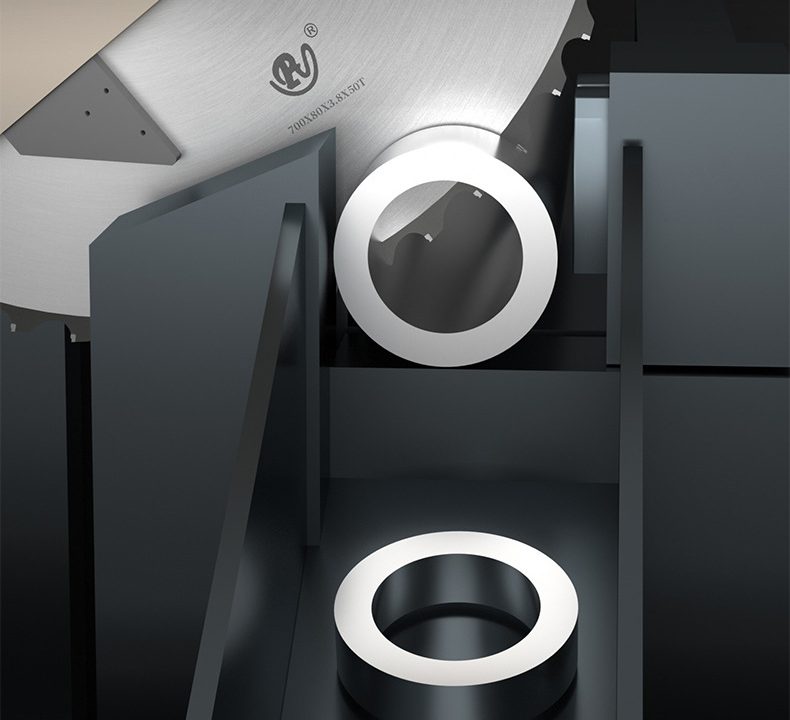

- Grinding Wheels: Inspect grinding wheels for any cracks or damage. Dress or truing wheels as necessary to maintain their shape and sharpness.

Quarterly/Annual Checks

- Calibration: Calibrate the machine to ensure accurate grinding operations.

- Thorough Cleaning: Perform a deep clean of the machine, removing any built-up debris or swarf.

- Systematic Lubrication: Apply a thorough lubrication to all components.

- Component Replacement: Replace worn-out components such as belts, filters, and seals.

2. Proper Usage

- Operator Training: Ensure that all operators are trained in the proper use of the machine. They should understand the machine’s capabilities and limitations.

- Workpiece Preparation: Clean workpieces before mounting them on the machine to avoid introducing contaminants.

- Correct Setup: Follow the manufacturer’s instructions for setting up the machine for each job. Incorrect setup can lead to poor quality grinding and potential damage to the machine.

- Safe Speeds: Operate the machine at the recommended speeds. Excessive speeds can cause overheating and premature wear of components.

- Grinding Wheel Selection: Use the correct grinding wheel for the material being worked on. Using the wrong wheel can result in subpar results and potential damage.

3. Safety Precautions

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses/goggles, hearing protection, and protective clothing.

- Emergency Shutdown: Familiarize yourself with the emergency stop procedures and practice them periodically.

- Machine Guards: Ensure all safety guards are in place and functioning correctly.

- Dust and Fume Extraction: Use proper dust and fume extraction systems to minimize inhalation risks.

- Fire Prevention: Keep fire extinguishers nearby and know how to use them.

4. **Documentation and Record Keeping

- Maintenance Logs: Keep detailed records of all maintenance activities, including dates, parts replaced, and any issues noted.

- Performance Logs: Track the machine’s performance over time to identify trends and potential issues early.

- Training Records: Document operator training sessions and certifications.

5. **Consult the Manufacturer

- Technical Support: If you encounter any issues or have questions, contact the manufacturer’s technical support team.

- Upgrades and Modifications: Consult the manufacturer before making any upgrades or modifications to ensure they are compatible and safe.

By following these guidelines, you can ensure that your gear grinding machine remains in optimal condition, operates efficiently, and provides consistent, high-quality results. Regular maintenance and adherence to safety protocols are key to prolonging the life of the machine and avoiding costly downtime.